Research content

In 2005, we succeeded in mass-culturing the edible microalgae Euglena outdoors for the first time in the world on Ishigaki Island. Since then, the methods of culturing, harvesting and drying have been constantly improved. The Production Technology Research Institute, located on the premises of the factory in Ishigaki Island, is in charge of research to continue producing microalgae at a lower cost, higher quality, more stable, and with less environmental impact. We are also researching culture methods that contain a high amount of specific components and methods for separating and recovering those components, and are exploring the potential of Euglena through the development of production technology. Utilizing the knowledge we have cultivated and the large-scale production equipment of our factories, we have been taking on the challenge of mass production of microorganisms other than Euglena in recent years.

Message from the director

Microalgaes such as Euglena and Chlorella will become one of Japan's national dishes in the near future. When it comes to national food, of course, not only one manufacturer, but many companies are competing with each other to form a large market. At that time, the algae we make are a bit different! From now on, we must carry out creative and strategic research on production technology in order for everyone to think. Until now, the Production Technology Research Institute has focused on research on methods for culturing the microalgae Euglena. In the future, we will take on unexplored issues such as more sustainable harvesting methods and drying processes, high quality settings that cannot be imitated anywhere else, and the development of new algae production technology.

Production Technology Research Institute

Director Takuto Takeuchi

Research case introduction

Controlling the odor and taste of edible Euglena

The Production Technology Research Institute is also responsible for quality improvement research on the microalgae Euglena produced at the factory. In edible Euglena, it is also important to control its odor and taste. Since the odor and taste of Euglena changes greatly depending on the manufacturing process, it is necessary to aim for an odor that is easier to eat and that is easier to incorporate into products.

- Research content

-

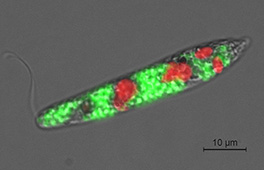

Microalgae Euglena has long been the subject of research as a microalgae that is easy to use for experiments. However, as an edible product, little research has been done on its odor and taste. In fact, Euglena, which contains both the nutrients characteristic of animals and plants, has an animal-like fishy odor and a plant-like green odor, so it is a problem that the taste of food is impaired.

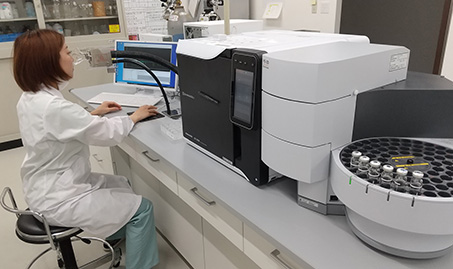

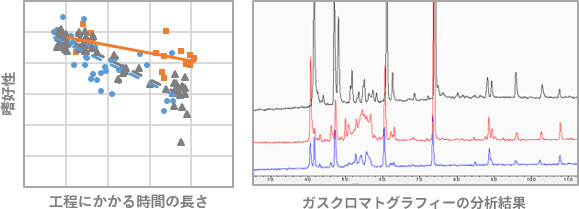

The Production Technology Research Institute focused on the time required for a certain process in the manufacturing process of edible Euglena, and found that the time correlates with the taste of Euglena as a food. Furthermore, we are trying to identify and control the components that affect the taste by analyzing the aroma components of Euglena by dedicated gas chromatography.

Considering mass production of algae with high content of unsaturated fatty acids

So far, the factory has produced chlorella and Euglena as edible microalgae. The Production Technology Research Institute is also conducting research to increase the lineup of materials to be produced. We aim to open up the potential of algae and contribute to people's health from various angles.

- Research content

-

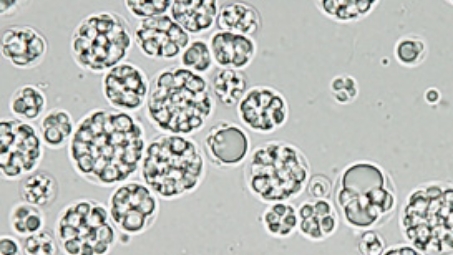

As a candidate for a new material to be produced, we have started research on the production of algae that can contain high amounts of unsaturated fatty acids. Although unsaturated fatty acids are recognized for their high functionality, their main source today is natural marine resources, which are also worried about depletion. If an artificial and industrial mass production method that utilizes microalgae culture technology is established, unsaturated fatty acids can be used stably.

The Production Technology Research Institute, by designing the optimal medium composition for culturing and examining harvesting and drying methods, will enable the production of a large amount of dry powder that can be held in both hands from a single small cell. became. Currently, we have succeeded in trial production of several hundred kilograms, and we are continuing research on improving the manufacturing process, aiming for commercialization.

A state of culture in a jar famentor

Algae powder with high content of unsaturated fatty acids produced by trial production