高校生からの夢だった、

バイオの力で人の役に立つこと

世界初の試み・日本のあぜ塗り技術を応用した

培養プールの建設でユーグレナ生産を低コスト化

2016年4月、武田は、バイオ燃料用のユーグレナの屋外培養に協力してくれる事業者を求めて日本全国を駆け回った。そして、3カ月後にようやく「ぜひ一緒に挑戦したい!」と名乗り出てくれたのが、三重県多気町に木質バイオマス発電所を保有する中部プラントサービスだ。

そして2016年9月。

ユーグレナ社は、中部プラントサービス、三重県、多気町の協力のもと、木質バイオマス発電所より、排出される排ガス・排水・排熱などを微細藻類の培養に必要な二酸化炭素源やエネルギーとして用いる燃料用微細藻類培養プールを木質バイオマス発電所の隣接地に建設することを発表した。

ユーグレナ社、中部プラントサービス、三重県、多気町の 4 者が協力を発表

その後、武田は工事の設計から施工の管理、さらには培養設備導入に向けた機器の選定まで、多くの人に協力してもらいながら手掛けていった。

しかし、まだ低コスト化への挑戦は終わっていない。

「さらに低コストで培養するにはどうしたらいいのだろう…

そうだ!培養プールの設計方法自体を変えてしまうのはどうだろうか?」

従来の微細藻類培養プールはコンクリートでできており、費用がかかるうえに工期も長い。培養設備の導入を進める中で、そもそも培養の土台となる培養設備自体を変えてしまうことを考えたのだ。

そこで、武田が目を付けたのは、100年以上の歴史を持つ岡山県の農業機械メーカー、小橋工業が保有する農耕技術、とりわけ水田造成技術だ。もともとは小橋工業より「水田造成技術を微細藻類の培養に活用できるのではないか」との提案をもらっており、2014年より微細藻類の効率的かつ安定的な培養方法の共同研究契約を締結し、研究を進めていたのだった。

そして、ついに2017年7月31日。

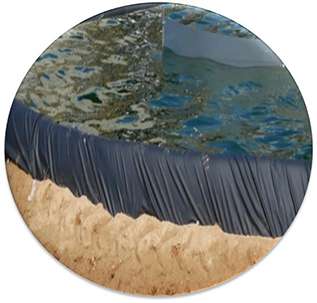

ユーグレナ社は小橋工業の水田造成のあぜ※塗り技術を応用した世界初のあぜ型微細藻類培養プールを建設・稼働を開始することを発表。

※あぜ…土を盛り上げて固めた田と田の間の仕切りのこと

三重県多気町のあぜ型微細藻類培養プール(1000㎡)

1,000平米規模の大型プールを実際に建設した結果、武田たちの研究により、土壌をあぜ型に固めて建設するため、コンクリートで建設された培養プールに比べて建設コストが 10 分の1程度となるほか、建設工期も4分の1程度となり、大量に必要となる燃料用微細藻類の生産コスト削減や生産量拡大への迅速な対応が可能となることが明らかになった。

あぜ型微細藻類培養プールの規模は、培養規模の拡大に合わせて2018年中には更に大型のプールの増設を進める予定だ。

武田は毎日試行錯誤しながらも、「光合成の力で世界を変えたい」という高校生の頃からの夢の実現に向かって、着実に一歩一歩進んでいる。

あぜ型微細藻類培養プールでの培養を発表した当日の三重の研究チーム(当時、左から立石・武田・花城)

2018年3月掲出

euglena Data

~日本独自のあぜ塗り技術を使ったあぜ型微細藻類培養プール~

登場人物

- バイオ燃料開発部

バイオ燃料開発課 チームリーダー武田 誠也 -

2012年4月入社。

入社からバイオ燃料開発課に所属し、石垣島、米国でバイオ燃料開発に向けた屋外培養を担当。2016年より、発電所からの排ガス・排熱等を利用したバイオ燃料研究に従事。「まだ夢の途中ですが、一歩ずつ着実に進んでいる実感があります。1日でもはやくユーグレナで飛行機が飛ぶ未来を実現させるために、多くの仲間とともに地道に研究を進めていきたいと思います」

euglena Projects

vol.00

バングラデシュの子どもたちを

救う素材を探せ。

vol.01

誰もなし得ていない、ユーグレナの

屋外大量培養技術を確立せよ。

vol.02

ユーグレナを

300億円市場に育て上げよ。

vol.03

バングラデシュの

全ての小学校に給食を。

vol.04

煙突から排出されるCO2で

ユーグレナを培養せよ。

vol.05

ユーグレナの化粧品事業を

立ち上げよ。

vol.06

日本初のバイオジェット燃料

製造プラントを建設せよ。

vol.07

「ミドリムシ」の名前を

武器にせよ。

vol.08

中国にユーグレナを

普及せよ。

vol.09

スーパーユーグレナを

獲得せよ。

vol.10

バングラデシュの

貧困問題を

緑豆事業で解決せよ。

vol.11

ユーグレナでタケダと

新商品を開発せよ。

vol.12

下水処理場の下水を活用し、

ユーグレナを培養せよ。

vol.13

ユーグレナの仲間の

「行動指針」を作成せよ。

vol.14

日本独自の技術で、

ユーグレナを培養せよ。

vol.15

仲間がより働きやすい

オフィスを追求せよ。

vol.16

ゆーぐりん保育園を

オフィスに併設せよ。

vol.17

ユーグレナで石垣島の

地域活性化に貢献せよ。

vol.18

ユーグレナの認知度を上げる

新商品を共同開発せよ

vol.19

ユーグレナのカフェを

石垣島で開店せよ。

vol.20

ユーグレナを飼料にして

比内地鶏を育成せよ。

vol.21

ユーグレナ入りディーゼル燃料を

いすゞ自動車と共同で実用化せよ。

vol.22

ユーグレナを使った

バイオ燃料を生産せよ。

vol.23

研究系ベンチャーを

ヒト、モノ、カネで支える

新しいファンドを確立せよ。

©2018 MELTIN MMI

vol.24

ユーグレナとクロレラで世界初の

ASC-MSC藻類認証を取得せよ。

vol.25

グループ企業との

シナジーを構築せよ。

vol.26

新しい仲間と、

遺伝子レベルで人を健康にせよ。

vol.27

自由が丘と

ユーグレナを普及せよ。

vol.28

ユーグレナサプリメントの

加工工場を立ち上げよ。

vol.29

理科のチカラで石垣島の

地域活性に貢献せよ。

vol.30

新しいユーグレナの

基幹化粧品を開発せよ。

vol.31

ロヒンギャ難民の

食料問題解決に貢献せよ。

vol.32

ユーグレナ由来の美容成分を

研究解明せよ。

vol.33

学生のチャレンジを応援!

通年採用を開始せよ。

vol.34

ユーグレナとクロレラで

ハラール認証を取得せよ。

vol.35

健康寿命を伸ばすユーグレナの

可能性を発見せよ。

vol.36

竹富島のクルマエビ養殖事業を

発展させよ。

vol.37

「G20軽井沢」にてユーグレナバイオディーゼル燃料で自動車を走らせよ。

vol.38

石垣島ユーグレナの魅力を伝えるキャラクターを企画せよ。

vol.39

CFO(最高未来責任者)を募集・選考せよ。

vol.40

国産カラハリスイカを

栽培せよ。

vol.41

日本初となる「バーチャルオンリー

株主総会」を開催せよ。

vol.42

次世代バイオディーゼル燃料を

普及させよ。

vol.43

コーポレート・

アイデンティティを刷新せよ。

vol.44

石垣島生まれの

ユーグレナを浸透させよ。

vol.45

ユーグレナ由来の

肥料研究を加速させよ。

vol.46

日本の空をバイオ燃料で

クリーンにせよ。

vol.47

オフィス環境を改善し、

仲間の生産性を向上させよ。

vol.48

化粧品における

サステナビリティを追求せよ

vol.49

次の新素材「ミドリ麹」の

価値を世に拡げよ。

vol.50

ユーグレナの

ESG経営を加速させよ

vol.51

未来世代アドバイザリーボードを

設置せよ。